Carbon Fibre Precursor Production Line

Description

Ny fomba famokarana fibre karbônina mialoha ny famokarana izay mampiasa ny Dimethyl Sulfoxide (DMSO) ho solvent, Acrylonitrile (AN) ho monomer voalohany, Acid Itaconic ho monomer faharoa, AIBN ho fanombohana hanana copolymerization binary, ary ny fihodinana maina maina. no safidy tsara indrindra nifanarahana tamin'ireo manam-pahaizana momba ny fibre karbônina.

Tech Specs:

| Tsia. | zavatra | Unit | fepetra arahana | fanamarihana |

| 1 | Linear Density | dtex | 1.15 | |

| 2 | Faharetana amin'ny sintona | CN/dtex | ≥4.0 | |

| 3 | Elongation | % | 12±2 | |

| 4 | Dimethyl Sulfoxide (DMSO) Content | % | <0.03 | |

| 5 | Ny votoatin'ny menaka | % | 0.5-0.1 | |

| 6 | Ny tahan'ny fahatapahana farany | % | <3 | |

| 7 | Hamandoana indray | % | ≤1 | |

| 8 | Bika Aman 'endrika | Tsy hita mibaribary tapaka Filament |

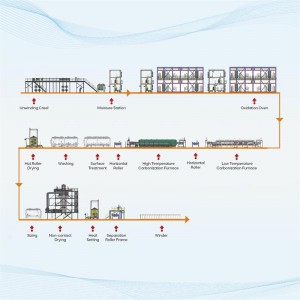

Dingana:

Fiomanana akora fototra —→ Fifangaroana Monomer —→ Copolymerization —→ Filtration voalohany —→ Esorina Monomer —→ Filtration faharoa —→ Neutralization Batch Mixed —→ Filtration Tertiary —→ Fitehirizana —→ Defoam —→ Fihodinana —→ fandroana (voalohany) —→ mihodikodina fandroana (Secondary) —→ spin bath (Tertiary) —→ Clean —→ Hot Stretching —→ Oiling —→ Draing —→ Steam Stretching —→ Heat Settings —→ Antistatic Treatment —→ Precursor winding

| Tsia. | zavatra | Unit | fepetra arahana | fanamarihana |

| 1 | Linear Density | dtex | 1.15 | |

| 2 | Faharetana amin'ny sintona | CN/dtex | ≥4.0 | |

| 3 | Elongation | % | 12±2 | |

| 4 | Dimethyl Sulfoxide (DMSO) Content | % | <0.03 | |

| 5 | Ny votoatin'ny menaka | % | 0.5-0.1 | |

| 6 | Ny tahan'ny fahatapahana farany | % | <3 | |

| 7 | Hamandoana indray | % | ≤1 | |

| 8 | Bika Aman 'endrika | Tsy hita mibaribary tapaka Filament |

Raw Fiomanana ara-pitaovana —→ Monomer Mixture —→ Copolymerization —→ Primary Filtration —→ Monomer Extract —→ Secondary Filtration —→ Mixed Batch Neutralization —→ Tertiary Filtration —→ Storage —→ Defoam —→ Spinning —→ spin bath (Primary) —→ spin fandroana (Secondary) —→ spin bath (Tertiary) —→ Clean —→ Hot Stretching —→ Oiling —→ Draing —→ Steam Stretching —→ Heat Settings —→ Antistatic Treatment —→ Precursor winding